Huge Cash Flow Improvement Opportunity

By Craig Theisen

The common practice of waiting until products are in production to remove cost can waste away a bunch of potential profit, cash flow, and company valuation.

A common pattern for companies is to design their products, launch them into production, and remove costs during production. Goals are established to remove costs during production, typically 1 to 3% of sales annually.

Instead, why not remove cost from their products during the design phase before they go into production? The C-O-S-T system, which stands for Cost Optimization System and Technique helps companies achieve just that.

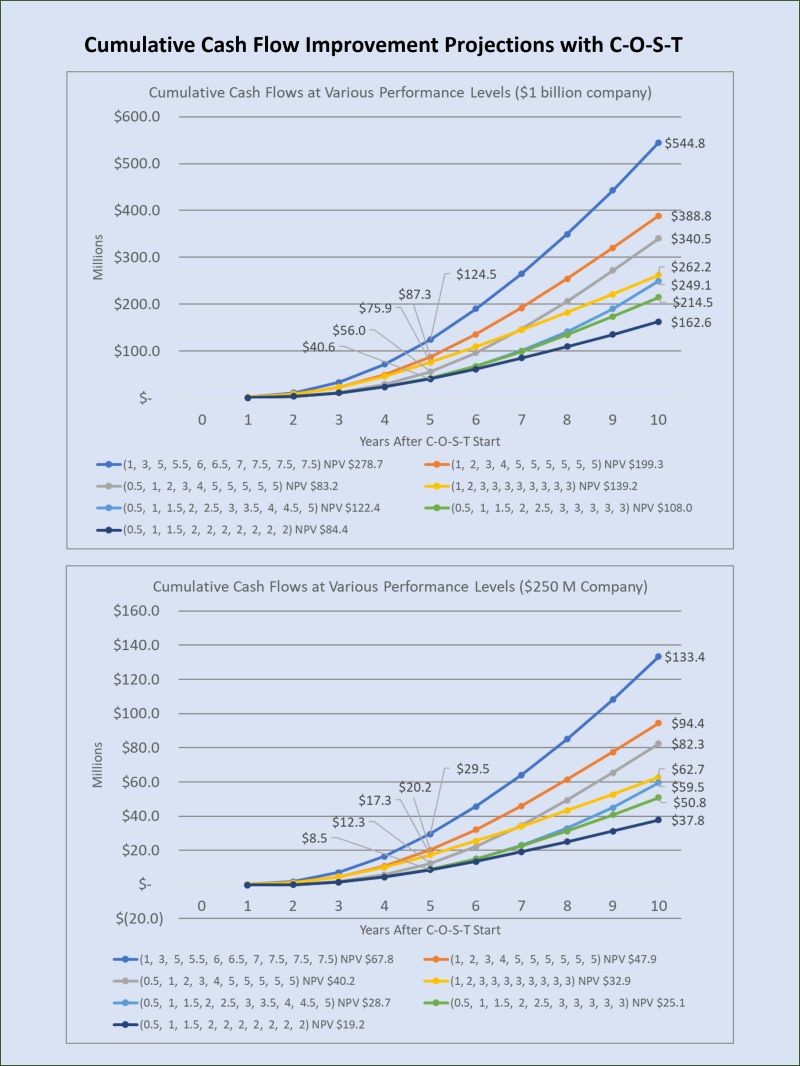

The illustration shows graphs of improved cash flow performance of two different sized companies by removing cost from their products during the design phase. The top illustration represents a company with $1 billion in annual sales. It assumes sales grow 5% annually and products are replaced every four years. Thus, they are launching $263 million next year, and so on. The lines show improved cumulative cash flow over 10 years. The numbers next to the lines in the legend are percent improvements in product cost, from year zero, in each of the ten years.

For example, the yellow line in the top graph indicates 1% improvement in the cost of products launched in year 1, 2% improvement (compared to year 0) in the new products launched in year 2, and 3% improvement in each of years 3-10. Basically, it would be getting new products launched at 3% lower product cost compared to year 0 and getting to 3% by year 3. This would result in $262 million in cash flow improvement over 10 years and $76 million in 5 years. The 10-year net present value is $139.2 million assuming a 10% discount rate. This assumes the profit improvement is not given away. Different levels of performance achieve different cash flow improvements.

With similar performance, a $250 million a year company has a 10-year cash flow improvement of $63 million and NPV of $33 million.

This is not difficult to do, but it does require a system to achieve it. Once in place, employees get better and better at removing cost from products during the design phase.